anodising sealing test|aluminum anodizing sealing : purchasing ASTM B136 describes a dye stain test to use to check seal quality on a pass/fail basis. The test requires Nitric Acid (40%) for two minutes and blue dye for 5 minutes, if there is a color change the parts fail (check out the spec . WEB1 de nov. de 2023 · Resultado do concurso 91 da +Milionária divulgado na noite de hoje, quarta-feira, 1º de novembro de 2023 (01/11/23). Prêmio está estimado em R$ 90 milhões. Os números são sorteados pela .

{plog:ftitle_list}

web3 dias atrás · 6 /10 - 579 votes. Played 966 599 times. Mahjong Variants. Mahjong Chain is an original variant of solitaire mahjong game in which you must connect two tiles with a straight path. Another feature of this free online mahjong, tiles fall and fill the empty spaces created by the previous eliminations.

anodized aluminum test

The most common of these test methods include film thickness measurement, the seal of anodic coatings, and conductivity measurement. Knowing the basics of each method and the influences that affect each . The sealing step is an important step employed in the aluminum anodization . ASTM B136 describes a dye stain test to use to check seal quality on a pass/fail basis. The test requires Nitric Acid (40%) for two minutes and blue dye for 5 minutes, if there is a color change the parts fail (check out the spec .

The best test you could is to dissolve a dark dye in oleic acid (the same present on your finger) and put a drop of it onto the anodised surface and remove it with a shower tap. You can graduate the effects of greasing letting a .

Seal Test. ASTM B 136 - Standard* method for measurement of stain resistance of anodic .

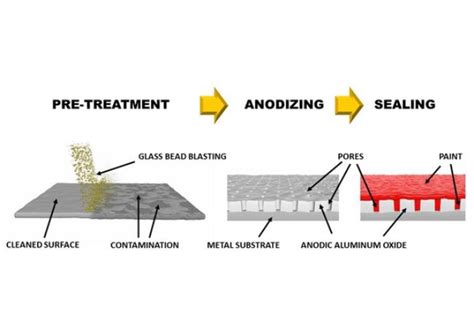

The authoritative public forum for Metal Finishing since 1989 -----Hot (boiling) DI water seal after anodizing. Current question and answers: Q. Anodizing is a finishing technique that I use to support my hobby in .Sealing is the final step in the anodizing process. Acidic anodizing solutions produce pores in the anodized coating. These pores can absorb dyes and retain lubricants but are also an avenue for corrosion. When lubrication properties .Both small and large anodizing systems need to have multiple tanks for completing the anodize process. A typical anodize line would involve a minimum of the following: Alkaline clean, rinse, etch, rinse, deoxidize, rinse, anodize, .

There are four types of sealing that are in common use for sulphuric anodising and hard anodising: Hot water sealing; Dichromate sealing . The industry standard benchmark neutral salt spray exposures of 336 hours (which we regularly test on 2024-T3 aluminium), do not show a difference between the two and they both reliably pass without issue. .

Seal the pores. After anodizing, you have to seal the microscopic pores on the surface of the part to prevent further corrosion and improve performance. Without sealing the pores, anodized parts may feel sticky to the touch. . To assess the quality of anodization, you should test how resistant the part is to abrasion and corrosion. If the . The dyeing step occurs after the anodizing process and before the sealing phase, ensuring the color penetrates the oxide layer effectively. This method is suitable for consumer products requiring both aesthetic appeal and functional durability. . Sealing Quality Test: Verifies that the anodizing process was completed with proper sealing to .

Abrasion resistance will vary with alloy and thickness of coating. Good dielectric properties. Corrosion resistance is good, but recommend sealing in 5% dichromate solution where increased corrosion resistance is required. Where extreme abrasion resistance is required do not seal as some softening is encountered. Type III Anodize Thickness GuideThe second volume covers architectural applications, hard anodizing, coloring and sealing of anodic oxide, properties and tests of anodic oxide, organic finishing, vitreous enameling and effluents. . Coating thickness can be measured by an "eddy current," nondestructive test instrument as per ASTM B 244-79, or by cutting a cross-section of .Test cell ø 13 mm: 3 - 200 µS Test cell ø 26 mm(1): 0,75 - 75 µS Note: Referenced to the standard measurement cell area of 133 mm2. Power supply: battery 9V6LR61 Dimensions (LxWxH): 160x80x30 mm Mass: 230 g (1) The meas. cells with a Ø of 6 mm or a Ø of 26 mm do not permit standardized measurements because the test areas areAnodize film thickness Anodize film uniformity Anodize film density Abrasion resistance Corrosion resistance Fade resistance Reflectivity Image clarity Insulative properties Adhesion Sealing: Applicable Tests G.M.C. Cass Test Ford fact test Salt spray Weatherometer Fadometer U.V. Con Acid dissolution (ASTM B136-63T) Weight test Microscopic test

CONTENTS FOREWORD INTRODUCTION TO ANODIZING ANODIZING TYPES SAFETY BASIC STEPS IN ANODIZING SEALING METHODS OF ANODIZED ALUMINUM WHAT YOU NEED SETTING UP AN ANODIZING SYSTEM TEMPLATE SYNTHESIS OF NANORODS AND NANOTUBES SURFACE CHARACTERIZATION CORROSION TESTING FINAL REMARKS . Different additives were added into the potassium fluorozirconate solution to prepare different nickel-free sealing reagents, with which the anodic oxidation film of aluminum alloy was sealed at room temperature. The phosphor chromic acid weight loss method was used to evaluate the sealing effects. Using electron scanning microscopy (SEM), the surface and .

anodized aluminum sealant

The Sealing Step in Aluminum Anodizing: A Focus on Sustainable Strategies for Enhancing both Energy Efficiency and Corrosion Resistance Stanley Udochukwu Ofoegbu, Fábio A. O. Fernandes and António B. Pereira Centre for Mechanical Technology and Automation (TEMA), Department of Mechanical Engineering, University of Aveiro, Campus . The parts failed this test only at 8 ASF, and even then only at elevated temperatures. The ADT is designed to test the corrosion resistance of parts, which is primarily dependent on how well the pores generated during anodization are plugged, i.e. the efficacy of the sealing step.The sealing of the anodized aluminum is a critical process in achieving the durability and extended functionality of anodizing. This article discusses the different methods for sealing the anodic coatings produced by using sulfuric acid, namely, hot deionized water, hot nickel acetate, midtemperature, cold, and dichromate sealing.7 - Reliability Test & Visual Inspection in Star 8 - Case Study 9 - Summary / Customer Remarks 2. How it Works Anodizing has 4 main stages: Cleaning and etching, anodizing, coloring and sealing. Stage 1: Cleaning & Etching 1.1 Cleaning detergent removes oils and contaminants from the parts surfaces, this can be done multiple times to ensure .

The seal process can be performed as a stand-alone, single-stage sealing process or as a duplex stage sealing process. The single-stage process requires seal times of approximately 10 minutes for coatings less than 0.5 mils .

Sealing techniques with silicates and fluoropolymers for hard anodizing will be explained. Dichromate and chromate sealing are not contemplated because they will be definitively proscribed in the European Union at the beginning of 2007. Therefore, we have to search for new sealing techniques with will not produce harmful impact on environment.Sealing is the step where the top of the honeycomb-like anodizing pores are swelled to lock the dye in and lock dirt out. Sealing is a science of its own, with older approaches like steam or boiling D.I. water being used, as well as newer mid temperature processes like nickel acetate, and low temperature seals like nickel fluoride. Schematic dilgrlm of I dynlmlc ..lling proc:eu. water sealing. The sealing quality relies on the pH value, purity, and temperature of hot water, sealing time, and current density used in anodizing. Ifthe sealing process is well controlled, hot water sealing is capable of substantially improving the corrosion resistance of anodized aluminum. EIS test encompassed a frequency range of 10 −2 to 10 5 Hz, with ten data points collected per decade. To ensure the accuracy of the experiments, each test was repeated with at least three samples. . As opposed to pure anodizing, sol-gel sealing significantly increases the low-frequency impedance modulus by an order of magnitude. Download .

Alternative to conventional aluminum anodize seals with an environmentally friendly seal process Harish Bhatt, METALAST International, Inc. Minden, NV 89423 . This is a common test for checking seal application. At one time, this was accepted as only test needed to check if part has been sealed. However, now it isSealing the Color: Once the metal has achieved the desired color, it’s essential to seal the surface. Sealing locks in color, enhances its durability, and protects against wear and fading. . This test confirms whether the anodizing meets the desired specifications and industry standards. Executing Adhesion Tests: Carry out adhesion tests .

The anodize coating is porous. Sealing chemically closes up the pores to keep out corrosion-causing chemicals. There is an ASTM test, ASTM B136, which is similar to the dye test you are running, . Those who are more serious about seal testing perform a weight-loss test, per ASTM B680. A panel or part is soaked in a chromic/phosphoric acid . Sealing. Seal the part using hot water (200ºF or 93ºC), which leads to the formation of hydrated aluminum oxide crystal responsible for sealing the pores. Other methods include steam and chemical sealing processes. Sealing allows you to lock in the colorants/dyes and improve the finished parts’ durability and corrosion resistance. Types of Aluminum Anodizing Processes. There are three types of aluminum anodizing processes. They are described in more detail below: Type I - Chromic Acid Anodizing: This process uses chromic acid as the electrolyte and produces the thinnest coating of all the methods, 2.5 μ (0.0001 in). Despite the reduced thickness, this process produces comparable .

Anodizing of aluminium and its alloys — Estimation of loss of absorptive power of anodic oxidation coatings after sealing — Dye-spot test with prior acid treatment.

Aperte o botão “Gerar Novo Sinal” para que o gerador de sinais Fortune Rabbit crie novas coordenadas. Anote a quantidade de rodadas normais e Turbo que aparecerão. No minuto pagante indicado, esteja com o jogo do coelho aberto e comece a jogar com um valor de aposta de sua preferência. Ao ultrapassar o horário, gere um novo sinal de .

anodising sealing test|aluminum anodizing sealing